Characters explanation

Ws= Load capacity of the swivel castor

Wf= Load capacity of the fixed castor

WT=Maximum weight to be carried

P= Deadweight (tare) of the trolley

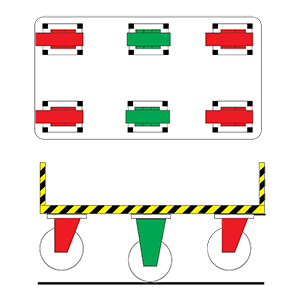

Below we present you all the possible options concerning Castors mounting:

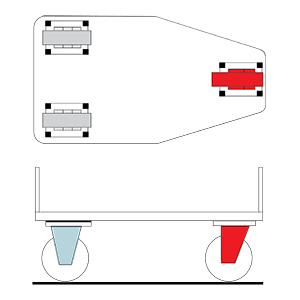

Option A

|

2 fixed + 1 swivel

It is preferable for small flexible constructions with light weights. Ws= (WT+P) x 0,4 |

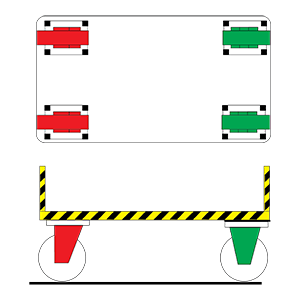

Option B

|

2 swivel + 2 fixed at the edges of the trolley

It is preferable for relatively high loads and long distances. Ws= (WT+P) x 0,35 |

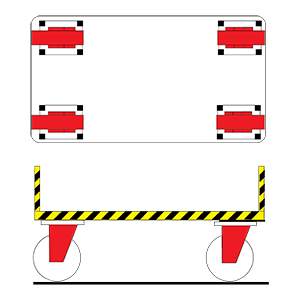

Option C

|

4 swivel at the edges of the trolley

It is preferable for applications which demand maximum flexibility, but in case of heavy loads it is not highly recommended for long distances. Ws= (WT+P) x 0,35 |

Option D

|

2 swivel + 2 fixed in the middle of the trolley sides It is preferable for flexible constructions for long distances on floors with channel and ramps. The fixed castors are usually placed higher than the swivel, so that the construction is being balanced on them. The handling is done from the side of the swivel castors.Ws= (WT+P) x 0,35 Wf= (WT+P) x 0,50 |

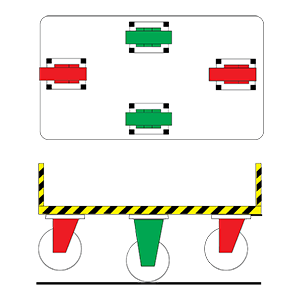

Option E

|

2 fixed in the middle of the long sides + 4 swivel at the edges of the trolley.

It is preferable for flexible and stable constructions for long distances on floors with channel and ramps. The fixed castors are usually placed higher than the swivel, so that the construction is being balanced on them. Ws= (WT+P) x 0,35 |

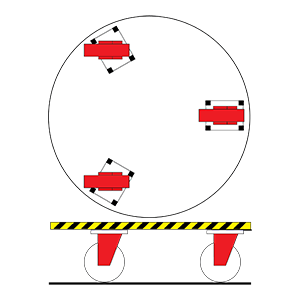

Option F

|

3 swivel at triangle disposition

It is preferable for circular trolleys or barrels. Ws= (WT+P) x 0,35 |

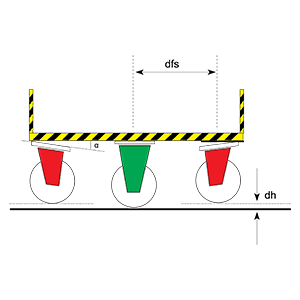

Note:

Note:

In options D and E the fitting top plate of the swivel castors should not be in parallel position with the floor of the trolley, but it must have the appropriate inclination, so as to be in horizontal position, while the wheel is in contact with the ground.

tan a = dh/dfs, where

dh= total height difference with swivel and fixed castors.

dfs= distance in between the center points of the fitting top plates of the swivel to the fixed castor.

is a Greek manufacturing company, producing the whole range of castors and wheels for institutional applications.

is a Greek manufacturing company, producing the whole range of castors and wheels for institutional applications.